Since 2002

Premium Industrial Caster Wheels Manufacturer

20+ Years of Rugged Mobility Solutions

ISO-Certified Smart Production

30,000+ Daily Output

About Our Company

Guangdong Goodich Hardware Co., Ltd

Guangdong Goodich Hardware Co., Ltd. revolutionizes material handling as the architect of “Durable Caster Wheels” philosophy. With 3.8 decades of vertical integration expertise, we’ve engineered Asia’s first intelligent caster production ecosystem capable of manufacturing 32,500 industrial caster wheels daily (11.8M annual capacity).

Our AI-driven smart management system ensures complete order transparency – 93% of clients report 48-hour real-time production tracking from material sourcing to final inspection. Specializing in three core categories:

- Durable Universal Casters (9 load capacity classes: 100kg-8,500kg)

- Specialized Industrial Casters (42 heat-resistant/chemical-proof variants)

- Equipment-Grade Mobility Solutions (2,136 custom specifications cataloged)

Serving 27 countries across logistics, aerospace, and medical sectors, our 78% repeat business rate validates our “User-First Co-Development” principle.

Showcase

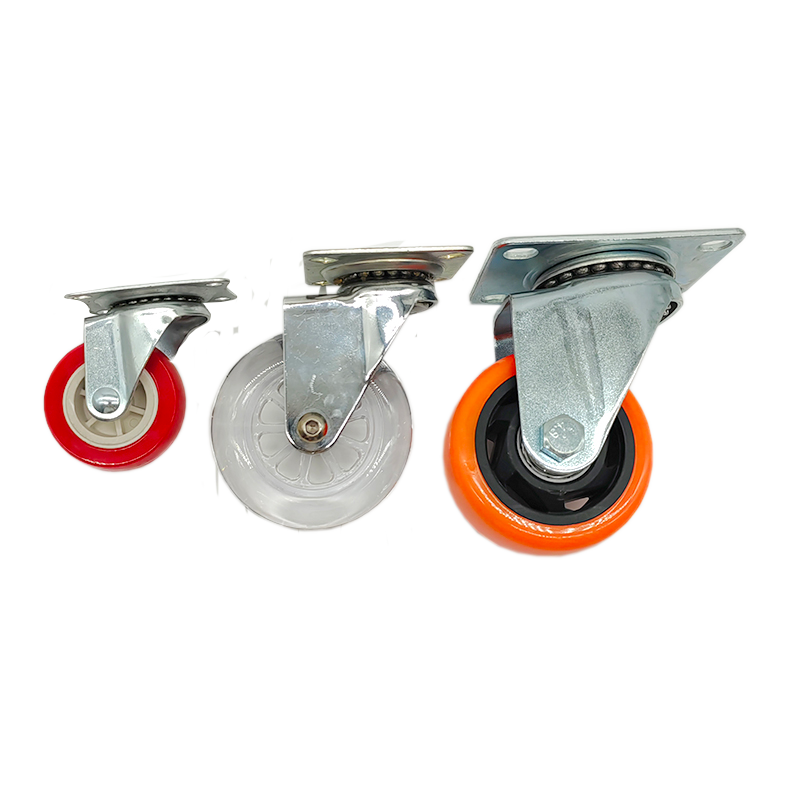

Industrial Caster Wheels

Featured Industrial Caster Solutions

Caster Categories

Production Steps and Process

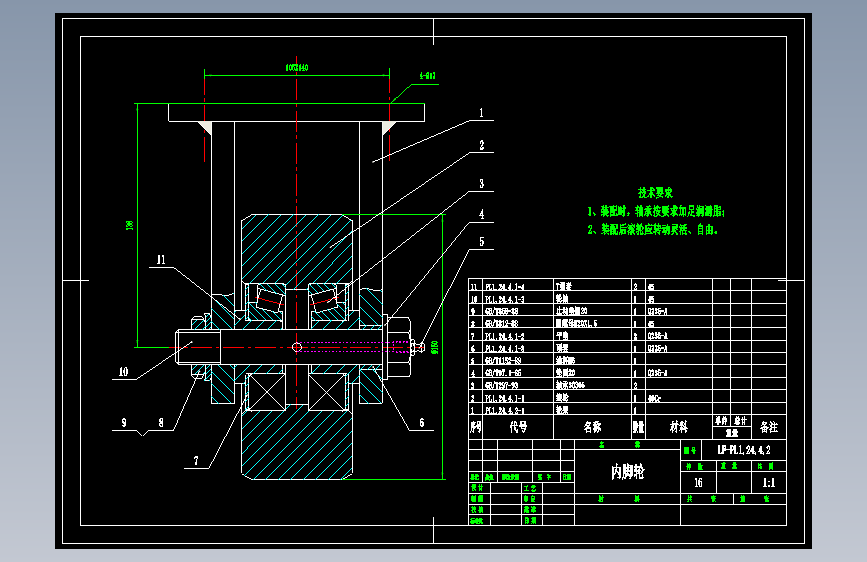

Design

Determine caster size, load capacity and tire material based on usage requirements. Design components like wheel body, bearings, mounting plate and fork using CAD software.

Material Selection

Choose materials such as polyurethane, nylon, rubber, stainless steel, etc., according to the operating environment and load requirements.

Wheel Body Manufacturing

Make wheel bodies via injection molding, die – casting or machining. For metal ones, processes like casting, forging, cutting and grinding are needed. Non – metal ones may require injection molding or compression molding.

Fork and Bracket Manufacturing

Metal forks are usually made by stamping, bending and welding metal sheets. Heat treatment may be applied to enhance their strength and durability.

Axle and Bearings

Axles and bearings, often made of wear – resistant steel, are key rotating components. Bearings can be ball, needle or plain bearings based on load and performance needs.

Caster Assembly

Install bearings in the wheel body and mount it on the fork. The fork and mounting plate are secured with bolts, welding or riveting.

Surface Treatment

Apply surface treatments like painting, powder coating or galvanizing to metal parts to improve corrosion resistance and appearance. Electro – plating operations are involved.

Quality Inspection

Test casters for load capacity, rotational smoothness and dimensional accuracy.

Manufacturer Advantages

Sustainability

89% recycled steel usage, 0-landfill policy

Vertical Integration

Control raw material (67 local suppliers) to final assembly – 22% cost advantage

R&D Leadership

14 patented technologies (including anti-vibration PU formula #CN201910358642.8)

Global Compliance

CE, REACH, RoHS certifications across product lines

Custom Engineering

48-hour rapid prototyping for special applications

Get a good price for Goodich

We are a Chinese caster manufacturer. If you need a large quantity, you can sign an annual order with us. We can give you a profit return of 1%-5%

(depending on the order amount)

Product List

Latest News

Free Sample Program

Experience our industrial caster wheels risk-free:

- No-Cost Samples: 3 units of standard models

- Custom Trials: 50% subsidy on prototype development

*98% sample approval-to-order conversion rate*