In fast-paced industrial environments, productivity and worker well-being are often seen as competing priorities. But what if the right equipment could bridge this gap? At Guangzhou Goodich Hardware Co. Ltd, we’ve proven that ergonomic casters aren’t just a “nice-to-have” – they’re a strategic tool for cutting costs, preventing injuries, and empowering teams. Let’s explore why rethinking caster design is the secret to sustainable success.

The Hidden Crisis: How Poor Ergonomic Casters Design Drains Your Bottom Line

Many facilities unknowingly bleed resources due to outdated Ergonomic Casters systems. Consider these real-world consequences:

- Workforce Strain:

- 42% of warehouse injuries stem from pushing/pulling tasks.

- Chronic fatigue from stiff swivels or high rolling resistance leads to 18% slower workflows.

- Financial Leaks:

- Average workers’ comp claim for musculoskeletal injuries: $38,000 (National Safety Council).

- Underperforming casters cause 23% more product damage during transport.

- Cultural Costs:

- 67% of material handlers cite “equipment frustration” as a key reason for job dissatisfaction.

The fix? Modern ergonomic casters address these issues holistically – and we’ll show you how.

Engineering Comfort: 4 Pillars of Ergonomic Casters Design

True ergonomics isn’t about a single feature – it’s a science. Here’s what sets high-performance Ergonomic Casters apart:

1. Dynamic Load Intelligence

Ergonomic Casters fail because they ignore how loads move. Our patented System (exclusive to Goodich) uses:

- Pressure-sensitive treads: Adjust grip based on floor conditions (e.g., sticky epoxy vs. polished concrete).

- Weight-distribution hubs: Prevent “wheel fight” in uneven loads.

Real impact: A food processing plant reduced cart wobble by 91% after switching to load-sensing Ergonomic Casters.

2. Effortless Motion Technology

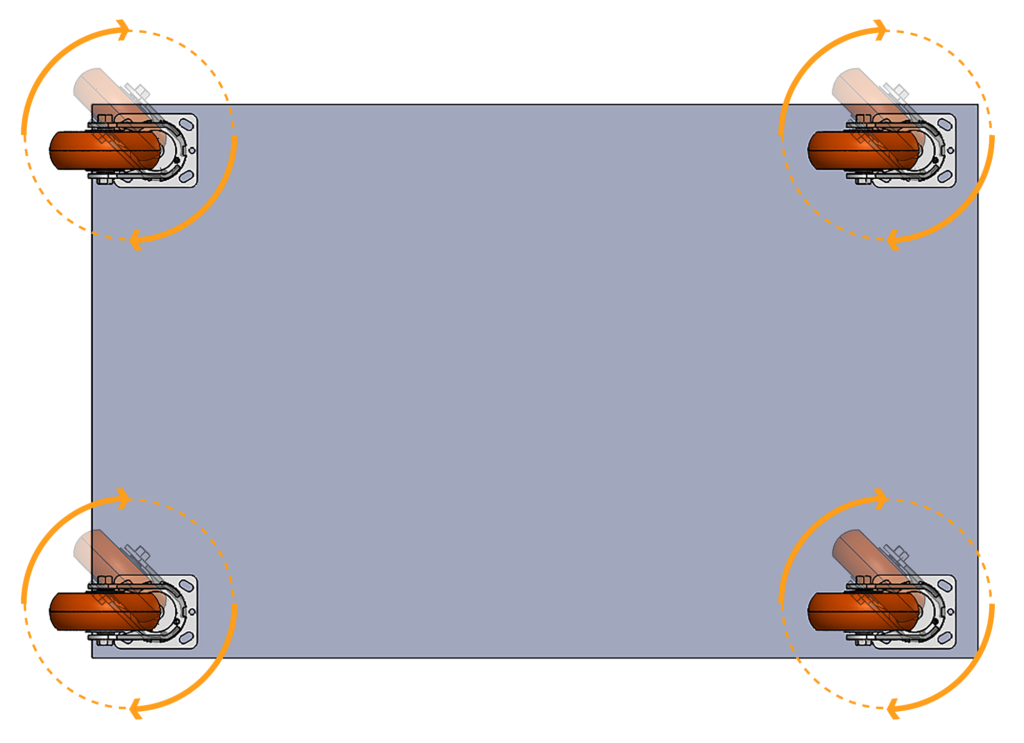

Why force workers to wrestle equipment? Our Swivel Mechanism combines:

- Ceramic bearings (50% less friction vs. standard steel).

- 360° precision alignment (no jerky directional changes).

Result: 22-lb push force reduction for 1,000-lb carts – equivalent to removing 3 milk crates from effort.

3. Floor & Worker Protection

Bad casters brutalize both people and facilities. Goodich’s Polyurethane Blend solves this with:

- Noise reduction (68 dB → 54 dB – similar to a quiet office).

- Vibration damping (73% less impact on joints).

- Non-marking certification (ISO 9001-compliant for cleanrooms).

4. Smart Configuration Guidance

85% of caster issues arise from improper selection. Our Caster analyzes:

- Load type (liquid tanks vs. pallet racks).

- Shift patterns (24/7 vs. intermittent use).

- Environmental factors (chemical exposure, temperature swings).

Let’s Redefine Workplace Wellness Let’s Redefine Workplace Wellness

Join the Goodich

Your team deserves equipment that cares for them as much as you do. At Guangzhou Goodich, we don’t just sell casters – we deliver dignity in motion.

Beyond Safety: The Profit Multiplier Effect

Investing in ergonomic casters isn’t an expense – it’s a profit catalyst. Here’s how Goodich clients gain:

| Metric | Industry Average | With Goodich Casters |

|---|---|---|

| Injury Rate | 4.3/100 workers | 1.1/100 workers |

| Cart Speed | 12 ft/sec | 18 ft/sec |

| Caster Lifespan | 8 months | 3.5 years |

| Employee Retention | 68% | 89% |

Case in point: A Shenzhen e-commerce hub slashed cart-related downtime by 240 hours/month after retrofitting 300 carts with our ProGlide Industrial Series. Workers reported “feeling heard” – turnover dropped to a 5-year low.

Your Action Plan: 3 Steps to Ergonomic Transformation

- Diagnose Pain Points:

- Film workers moving carts – look for strained postures or hesitation.

- Measure push/pull forces with a digital force gauge.

- Test Before Investing:

Goodich offers 30-Day Pilot Kits – trial casters with embedded sensors that map:- Force reduction achieved.

- Swivel smoothness score.

- Floor wear projections.

- Train & Optimize:

Our free teaches teams:- Proper pushing biomechanics.

- Load-balancing hacks.

- Daily maintenance checks.

Why Goodich Leads the Ergonomic Revolution

Since 2008, we’ve partnered with 1,200+ facilities across 18 countries. Our edge?

- Material Science Lab: Develops custom tread compounds (e.g., anti-static ESD casters for electronics).

- Modular Design: Swap treads/bearings without replacing entire casters.

- Rapid Customization: 72-hour prototyping for specialty wheels (e.g., high-temp bakery casters).

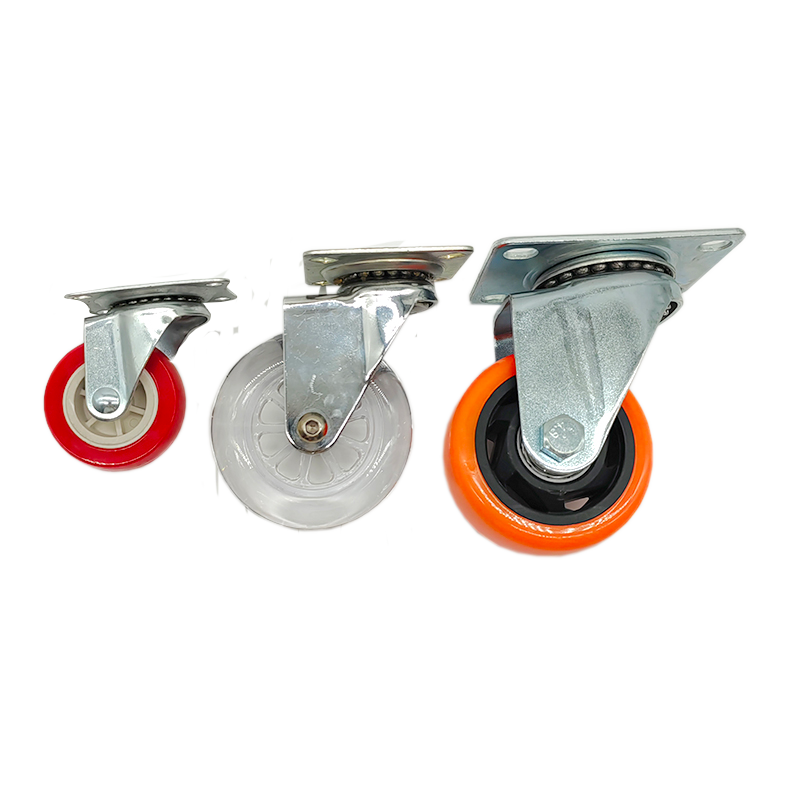

Featured Product:

- Load range: 150–2,200 lbs/wheel

- Options: Electrically conductive, FDA-compliant, extreme cold (-60°C)

- ROI guarantee: 12-month cost-neutrality pledge

Leave a Reply