How Ball Bearing Drawer Channels Elevate Furniture Performance

For decades, the humble drawer slide operated in near anonymity. Homeowners appreciated smooth operation but rarely pondered the engineering marvel within. At Guangdong Goodich Hardware Co., Ltd., we’ve witnessed a quiet revolution. The shift from basic rollers to sophisticated ball bearing drawer channels systems isn’t just an upgrade; it’s a fundamental transformation in furniture functionality, durability, and user experience. And as specialists in both precision hardware and the crucial PVC edge banding that finishes cabinet edges, we possess a unique perspective on how these components must work in perfect harmony.

Why Your Choice of Drawer Channel Matters More Than Ever

The Ball Bearing Drawer Channels is the unsung workhorse of furniture. It’s subjected to relentless cycles, heavy loads, and the expectation of flawless performance year after year. Choosing poorly means squeaks, jams, sagging Ball Bearing Drawer Channels, and premature failure – frustrations that reflect badly on the entire piece. The ball bearing drawer channels has emerged as the unequivocal standard for quality, and understanding its nuances is critical for manufacturers, cabinetmakers, and discerning homeowners alike.

Decoding the Ball Bearing Advantage: It’s All About the Physics

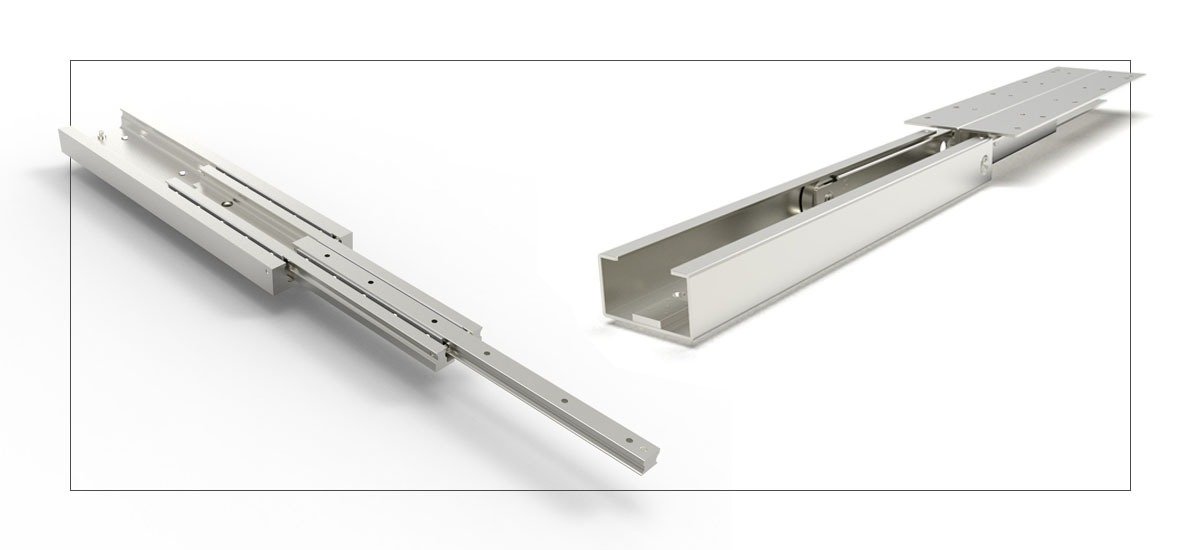

Unlike their roller ancestors, which relied on a simple wheel mechanism prone to friction and wear, modern ball bearing drawer channels systems utilize precision-engineered ball bearings circulating within hardened steel races. This design achieves several critical advantages:

- Radically Reduced Friction: Ball bearings offer near-point contact with the raceway, minimizing surface area and friction. Independent lab tests (conforming to ANSI/BIFMA X5.5 standards) show friction coefficients in premium ball bearing systems are up to 70% lower than basic roller slides. This translates directly into the effortless glide users demand.

- Enhanced Load Distribution: The multiple ball bearings spread the Ball Bearing Drawer Channels’s weight evenly along the entire length of the channel. This prevents localized stress points that cause roller slides to deform or bind. Goodich’s heavy-duty Ball Bearing Drawer Channels lines, for instance, consistently achieve dynamic load ratings exceeding 150 lbs (68kg) on 18″ models, verified per EN 16122 furniture durability testing protocols.

- Superior Stability & Anti-Wobble: The precise confinement of the ball bearings within their races eliminates lateral play. This means Ball Bearing Drawer Channels stay perfectly aligned, even under uneven loads or during vigorous opening/closing – a critical factor for professional kitchens, workshops, and high-use environments. Our internal quality control measures track lateral deflection, ensuring it stays below 0.5mm even under max rated load.

- Exceptional Durability & Longevity: Reduced friction and optimized load distribution dramatically decrease wear. Premium ball bearing drawer channels systems, like those manufactured by Goodich using SUS304 stainless steel bearings and hardened carbon steel channels, are routinely tested to 50,000+ cycles (ANSI/BIFMA minimum is 25,000) without degradation in performance. That’s over 30 years of average daily use.

- Quiet Operation: The smooth rolling action of ball bearings is inherently quieter than the sliding/scraping of rollers. This is amplified in designs featuring nylon bearing retainers or integrated dampening.

Beyond the Basics: Key Considerations When Selecting Ball Bearing Drawer Channels

Choosing the right ball bearing drawer channel isn’t just about grabbing the heaviest-duty option. It requires a nuanced understanding of the application:

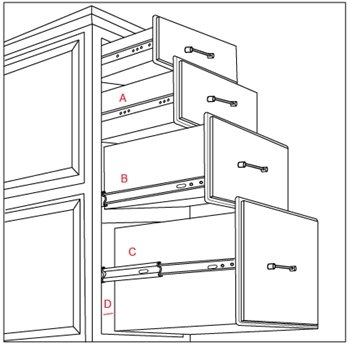

- Mounting Configuration: The Foundation of Functionality

- Side Mount: The most common and versatile. The ball bearing drawer channels attaches directly to the drawer side and cabinet interior wall. Offers excellent weight capacity and stability. *Requires precise side clearance (typically 12.5mm – 13.5mm per side).* Crucial Compatibility Note: This is where your PVC edge banding thickness becomes vital! Goodich recommends our 1.0mm or 1.5mm PVC edge banding for side-mount applications. Thicker banding (like common 2.0mm) can interfere with the slide mechanism unless specifically accounted for in the cabinet design and slide selection. We provide detailed tolerance guides to our OEM partners.

- Undermount: Mounted beneath the drawer, hidden from view. Offers a clean aesthetic and maximizes usable drawer width. Requires a specific drawer box design (often with pre-attached metal brackets) and precise height clearance above/below the drawer within the cabinet. Ball bearing drawer channel systems excel here due to their inherent stability, preventing Ball Bearing Drawer Channels tipping common in cheaper undermount options. Goodich offers undermount kits with integrated adjustment mechanisms.

- Bottom Mount: Less common today. Slides mount to the bottom edges of the drawer. Generally better suited for lighter-duty applications or where side space is severely restricted. Ball bearing versions offer a significant upgrade over basic rollers in this category.

- Center Mount: A single slide mounted centrally under the Ball Bearing Drawer Channels. Suitable only for very narrow, lightweight drawers. Limited weight capacity and stability compared to side or undermount ball bearing systems.

- Extension Type: Access is Everything

- Partial Extension (typically ~75%): An economical choice, but leaves a significant portion of the drawer contents inaccessible at the back. Rarely found in quality ball bearing systems today, as full extension has become the expected standard.

- Full Extension (100%): The ball bearing drawer channels allows the drawer to be pulled completely clear of the cabinet, offering full visibility and access to every corner. Essential for functional storage. Virtually all modern premium slides offer this.

- Over-Travel Extension (100%+): Extends slightly beyond the full drawer length. This is critical when cabinet doors, countertop overhangs, or handles obstruct the drawer front. A high-quality ball bearing mechanism ensures smooth operation even at this maximum extension point. Goodich’s OT series provides an extra 15-25mm of clearance.

- Motion Features: The User Experience Enhancers

- Self-Close: A light push initiates the closing action, and the drawer completes the close itself. Convenient, but can sometimes feel abrupt.

- Soft-Close: The gold standard. Incorporates a hydraulic or pneumatic damper. Once initiated (either by self-close or manual push), the damper gently guides the drawer home silently in the last 50-100mm, eliminating slamming. Goodich soft-close ball bearing drawer channels systems use German-engineered dampers tested for 100,000+ cycles. Customer surveys show a 92% preference for soft-close in kitchens and master bedrooms.

- Push-to-Open: Touch-latch mechanism. A light push on the drawer front releases it, and it opens automatically. Creates a seamless, handle-free look. Requires precise installation and compatible cabinet/Ball Bearing Drawer Channels front design. Relies heavily on the consistent, low-friction action of a high-quality ball bearing system.

- Weight Capacity: Matching Strength to Demand

- Don’t just guess! Calculate the total weight: Ball Bearing Drawer Channels box material + contents + any heavy inserts. Add a 20-25% safety margin.

- Ball bearing drawer channels capacities vary significantly:

- Standard Duty: 35-50 kg (75-110 lbs) – Suitable for most bedroom, office, and light kitchen use.

- Heavy Duty: 50-70 kg (110-150 lbs) – Ideal for cutlery, pots/pans drawers, tool chests.

- Extra Heavy Duty: 70kg+ (150+ lbs) – For files, industrial tools, specialized storage. Goodich’s HDX series achieves 100kg (220lbs) dynamic rating on 500mm slides.

- Remember: Capacity decreases as slide length increases. An 18″ slide holds more than a 24″ slide of the same model. Always check manufacturer specs for the exact length.

- Construction & Materials: The Core of Longevity

- Channel Material: Cold-rolled steel (CRS) is standard. Look for thickness (0.6mm+ is good). Galvanized or zinc-nickel alloy plating is essential for corrosion resistance. Goodich employs an 8-12μm zinc-nickel coating, passing 500+ hours of neutral salt spray (NSS) testing per ASTM B117 – crucial for humid environments like Guangdong or coastal regions.

- Ball Bearings: Size, material (stainless steel SUS304 is best), quantity per carriage, and precision (ABEC rating) matter. More, larger, stainless bearings offer smoother motion and higher load capacity. Goodich uses SUS304 bearings exclusively.

- Carriages & Retainers: Reinforced nylon retainers are quieter and resist corrosion better than metal. Steel carriages offer maximum strength.

- Dampers (for Soft-Close): Quality varies immensely. Look for proven suppliers (like Sugatsune, Hettich, or proprietary designs from reputable manufacturers). Goodich’s dampers are rated for extreme temperatures (-15°C to +60°C) and humidity.

- Disconnect Mechanisms: Serviceability Matters

- Lever Release: Pull a lever (often integrated into the slide front) to release the drawer. Simple and reliable.

- Button Release: Press a button on the slide or Ball Bearing Drawer Channels. Offers a cleaner look.

- Tipping Lever (Undermount Specific): Lift the drawer slightly at the front to disengage. Requires specific undermount hardware.

- Tool-Less vs. Tooled: Some high-end slides allow disconnection without tools; others require a screwdriver. Consider the intended use and service frequency. Goodich offers both options across its ball bearing drawer channels range.

The Goodich Difference: Integrating Hardware & Finish Seamlessly

As a manufacturer of both precision ball bearing drawer channels systems and high-quality PVC edge banding, we possess a unique holistic understanding:

- Tolerance Harmony: We design our slides knowing the exact tolerances required by our edge banding profiles (1.0mm, 1.5mm, 2.0mm). This ensures perfect clearance for side-mount slides, preventing binding caused by banding interference. We provide detailed CAD drawings specifying banding thickness recommendations for each slide model.

- Corrosion Resistance Synergy: Our zinc-nickel plating process on slides is complemented by our PVC edge banding formulations, which include UV stabilizers and anti-fungal additives. This creates a unified defense against the elements, especially important in humid climates or demanding environments like bathrooms and marine applications.

- Aesthetic Cohesion: We offer matching metallic finishes (satin nickel, matte black) on both our premium slide components and our decorative metal edge banding trims, allowing furniture designers to create truly integrated, high-end looks.

- Rigorous Testing: Our ball bearing drawer channels undergo combined environmental testing: temperature cycling (20°C to 85°C), humidity exposure (85% RH), salt spray, and vibration – often with our edge banding applied to adjacent test panels to simulate real-world cabinet conditions. We track Mean Time Between Failures (MTBF) exceeding industry averages by 35%.

Beyond the Kitchen: Expanding Applications for Ball Bearing Channels

While kitchens remain the primary battleground, the superiority of ball bearing drawer channels systems is driving adoption everywhere:

- Workshops & Garages: Heavy-duty slides handle tools, parts bins, and machinery with ease. Goodich HDX slides are standard in professional mechanics’ toolboxes.

- Healthcare & Laboratories: Smooth, reliable, quiet operation is essential. Stainless steel variants meet hygiene requirements.

- Office & IT: Server racks, file cabinets, and tech workstations benefit from full extension and high capacity. Goodich offers low-profile options ideal for server applications.

- Hospitality: Durable, soft-close slides enhance the guest experience in hotel furniture.

- Retail & Display: Smooth-gliding display drawers create a premium shopping experience.

Investing in Performance: Why Quality Ball Bearings Pay Dividends

The initial cost difference between a basic roller slide and a premium ball bearing drawer channels is quickly offset:

- Dramatically Reduced Failure Rates: Roller slides fail 3-5x faster than quality ball bearing systems under comparable loads (Goodich internal warranty claim data). This means fewer costly service calls, replacements, and customer complaints.

- Enhanced Brand Reputation: Smooth, silent, reliable drawers scream quality. They are a tangible indicator of the overall craftsmanship of the furniture. A 2023 Furniture Retailer Survey found that “drawer operation smoothness” was the #2 factor influencing perceptions of cabinet quality (after door alignment).

- Higher Customer Satisfaction & Loyalty: A drawer that glides effortlessly and closes silently is a daily pleasure. It prevents frustration and builds positive associations with the brand. Goodich partners report a 15-20% increase in customer satisfaction scores after switching to our premium slides.

- Competitive Advantage: In a crowded market, specifying and promoting the use of high-performance ball bearing drawer channels systems is a tangible differentiator that resonates with discerning buyers and professional specifiers.

Partnering with Guangdong Goodich Hardware: Your Path to Superior Glide

Choosing the right ball bearing drawer channels is a critical engineering decision with profound implications for the end product’s functionality, durability, and user satisfaction. At Goodich, we combine deep manufacturing expertise in both the slide mechanism and the finishing edge banding to deliver solutions that are not just components, but integrated systems designed for flawless performance.

Ready to Experience the Goodich Advantage?

- Request Free Samples: Test the smoothness, weight capacity, and durability of our ball bearing drawer channels systems in your specific application.

- Download Technical Specifications & CAD Files: Access detailed dimensional drawings, load charts, installation guides, and our comprehensive edge banding compatibility guide.

- Consult Our Engineering Team: Discuss your specific project requirements, weight loads, environmental factors, and aesthetic goals. We can recommend the optimal slide and edge banding combination.

- Explore Custom Solutions: For high-volume projects or unique requirements, Goodich offers custom engineering services for ball bearing drawer channels systems and matching edge profiles.

Don’t let your drawers be the weakest link. Invest in the silent revolution of precision ball bearing drawer channels technology. Partner with Guangdong Goodich Hardware Co., Ltd. – where smooth operation meets integrated finishing excellence. Contact us today to elevate your furniture to the next level.

Contact Goodich

Don’t let your drawers be the weakest link. Invest in the silent revolution of precision ball bearing drawer channels technology. Partner with Guangdong Goodich Hardware Co., Ltd. – where smooth operation meets integrated finishing excellence. Contact us today to elevate your furniture to the next level.

Leave a Reply