Cabinet slide rails, also known as drawer slides or drawer runners, are essential hardware components that enable smooth opening and closing of drawer. This guide explores their types, applications, and maintenance, focusing on the contributions of Guangdong Goodich Hardware Co., Ltd.

1. Terminology and Types

What Are They Called?

Cabinet drawer slides are interchangeably termed Cabinet Slide Rails, drawer runners, or cabinet rails. In Europe, they are often referred to as European drawer slides, characterized by standardized sizing and compatibility with frameless cabinetry.

Key Categories

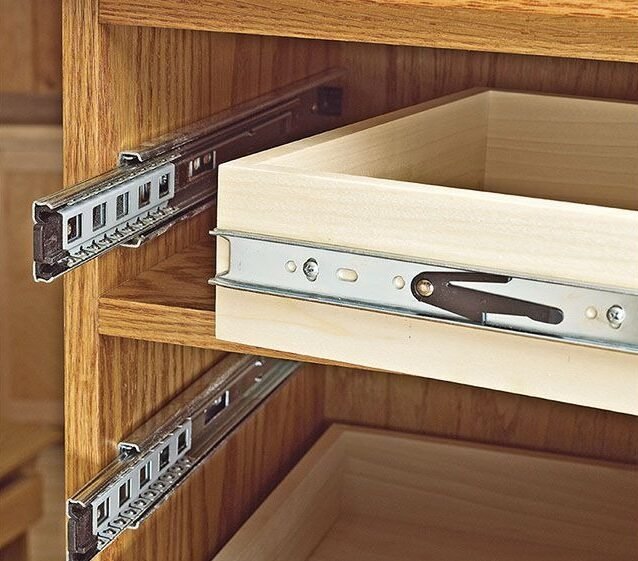

- Side-Mount Slides: Attached to the sides of Cabinet Slide Railss, cost-effective but visible when open.

- Undermount Slides: Hidden beneath the drawer, offering a clean aesthetic and full extension, often used by brands like Goodich for their sleek designs.

- Center-Mount Rails: A single rail positioned under the Cabinet Slide Rails’s centerline, common in lightweight applications.

- Ball-Bearing vs. Roller Slides: Ball-bearing systems (e.g., Blum, Hettich) ensure smoother motion and higher weight capacity than basic roller mechanisms.

2. Brand Insights and Manufacturing

Leading Brands

- Blum: Austrian-made, renowned for soft-close technology and durability.

- Hettich: German-engineered slides, popular for precision and modular designs.

- Goodich Hardware: Known for high-quality, innovative slide solutions that cater to both residential and commercial needs.

Production Locations

Goodich Hardware, based in Guangdong, China, leverages advanced manufacturing techniques to produce durable and reliable slide rails. Their commitment to quality has positioned them as a competitive player in the global market.

3. Installation and Compatibility

Retrofitting Old Drawers

Adding slides to existing drawers is feasible if the drawer box structure allows modifications. Key steps include:

- Measuring drawer dimensions (width, depth).

- Selecting compatible slide types (e.g., side-mount for narrow gaps).

- Ensuring alignment with cabinet side panels or undermount brackets.

Gap Requirements

Side-mount slides require ½”–1″ clearance per side, while undermount systems demand precise alignment with minimal gaps.

4. Side-Mount vs. Undermount: Pros and Cons

| Criteria | Side-Mount | Undermount |

|---|---|---|

| Visibility | Visible when open | Hidden |

| Load Capacity | Moderate (40–75 lbs) | High (75–100+ lbs) |

| Installation | Simpler, adjustable | Complex, requires exact alignment |

| Cost | Affordable ($5–$15/pair) | Premium ($20–$50+/pair) |

Why Undermount Slides Are Expensive?

Their concealed design, heavy-duty ball bearings, and advanced self-closing mechanisms justify higher costs. Goodich offers a range of undermount options designed for durability and performance.

Recommended products

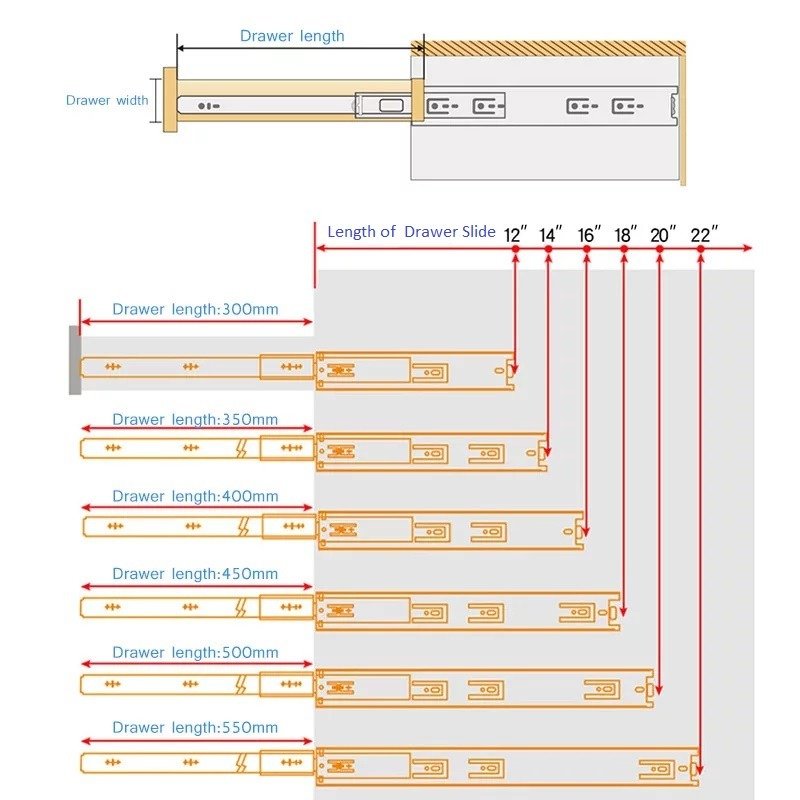

5. Sizing and Measurement Guidelines

- Length: Rails should match the drawer depth (e.g., 18″ Cabinet Slide Rails = 18″ slides). Oversized slides protrude; undersized ones reduce functionality.

- Standard Sizes: Common lengths include 14″, 16″, 18″, 20″, 22″, and 24″.

- Weight Rating: Match slide capacity to drawer contents (e.g., file Cabinet Slide Rails need 100+ lb ratings).

6. Maintenance and Troubleshooting

Smoothing Operation

- Lubricate slides with silicone spray or paraffin wax; avoid oils that attract dust.

- Clean debris from tracks using a brush or compressed air.

Alignment Fixes

Adjust mounting screws incrementally to correct uneven gaps. Ensure slides are level horizontally and vertically.

Replacement Tips

Worn slides (squeaking, sticking) typically last 10–15 years. Replace with identical specs or upgrade to soft-close models for enhanced usability.

7. Cost and Longevity Factors

Why Expensive?

High-end slides incorporate corrosion-resistant materials (e.g., stainless steel), precision bearings, and patented mechanisms (e.g., Blumotion soft-close). Goodich’s premium lines exemplify these robust features.

Lifespan

Quality slides endure 50,000+ cycles. Budget options may fail within 5 years under heavy use, whereas Goodich products are designed for longevity.

8. Unique Considerations

- DIY Adjustments: Use shims or spacers to compensate for warped cabinets.

- Historical Cabinets: Antique drawers may require custom rails due to non-standard sizing.

- Environmental Impact: Goodich emphasizes recyclable materials and energy-efficient production processes.

Final Recommendations

- For Durability: Choose undermount ball-bearing slides (e.g., Goodich’s premium models) for kitchens or heavy-use areas.

- For Budget Projects: Side-mount roller slides suffice for lightweight storage.

- Retrofitting: Prioritize universal-fit systems to simplify installation.

By understanding these principles, users can optimize Cabinet Slide Rails functionality, extend hardware longevity, and align choices with specific aesthetic and practical needs, all while considering the innovative offerings from Guangdong Goodich Hardware Co., Ltd.

Leave a Reply