Corrosion-Resistant Slides & Rails

Industrial Heavy Duty Drawer Runners 10-230kg

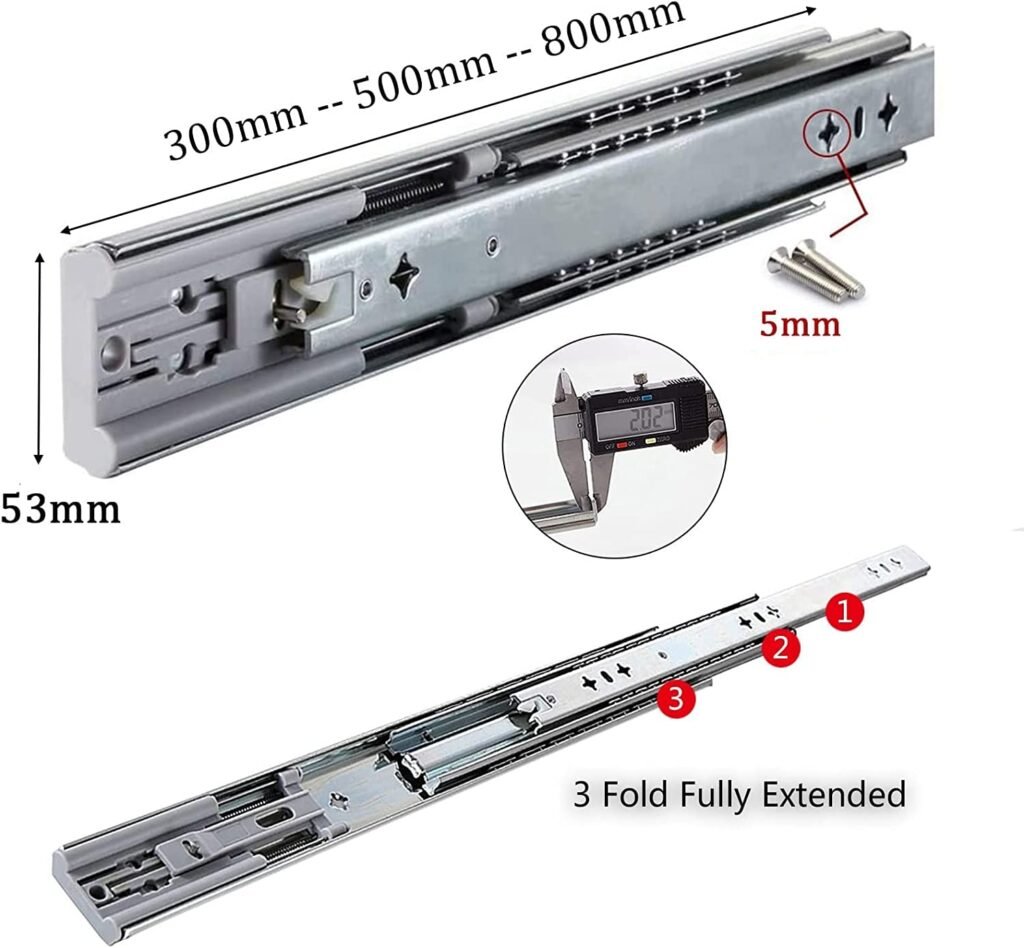

Engineer-certified heavy duty drawer runners with 100% extension, tool-free locking & soft-close. Supports 300kg dynamic loads. ISO 1461 galvanized steel.

Hot-dip galvanized layer (thickness ≥ 80μm), passed the salt spray test for 1200 hours without rust (ordinary steel only 400 hours), suitable for harsh environments such as high humidity workshops and coastal factories

Full extension + over-travel protection

Patented bearing design: three-row ball bearing system (8mm diameter), supports 500mm track extension to 1000mm, and the drawer is fully exposed without dead angles

Anti-derailment mechanism: integrated mechanical lock at the end to prevent accidental slippage caused by vibration (passed 100,000 vibration tests)

Military-grade galvanized steel construction

Our Company

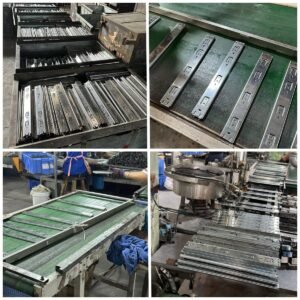

Guangdong Goodich Hardware Co., Ltd

Guangdong Goodich Hardware Co., Ltd. was established in 2002. It is a professional manufacturer of high-end drawer slides headquartered in Guangdong, focusing on providing high-performance drawer guide solutions for kitchen, office, industrial and automotive fields to customers around the world. With technological innovation and quality control as the core, the company has an annual production capacity of 500 million sets of slides, 85% of which are automated workshops. It has passed ISO 9001 certification and quality management system, and achieved a precision manufacturing standard with a failure rate of only 0.1%. Its products include side-mounted and concealed installation slides

- Soft Close and Full Extension designs, using ball bearings and galvanized/stainless steel materials, and special anti-corrosion coatings on the surface to improve durability;

- Customized services support OEM/ODM, and can adapt to material, size and color requirements (such as powder coating process);

- Global cooperation covers more than 2,000 companies in more than 50 countries, helping 300+ customers achieve 200% sales growth, and providing warranty and full compensation for defects

Drawer Slide Product Catalog

Covering 2000+ industrial-grade products such as heavy-duty drawer slides, linear guides, telescopic systems, etc., to meet the diverse load-bearing needs from home cabinets to aerospace equipment

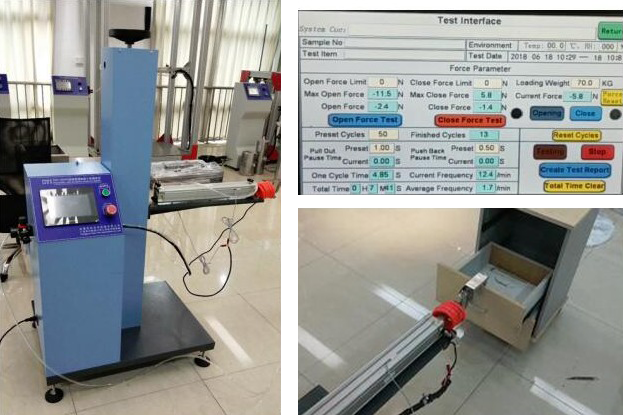

1. Dynamic Load Stress Testing: 45kg Real-World Scenario Simulation

- Multi-axis Load Simulation:

Following ASTM D4169 transportation standards, slides withstand 5Hz vibration (equivalent to 3,000km truck transport) with zero deformation under 45kg load. - Asymmetric Load Test:

30% offset loading (simulating toolbox applications) shows slide displacement <0.3mm – exceeding ISO 9001’s <1mm requirement.

2. Mechanical Endurance Testing: 100,000-Cycle Breakthrough

- Accelerated Aging Protocol:

- After 50,000 cycles: Ball wear ≤8μm (industry avg. 15μm), noise ≤25dB maintained

- 100,000-cycle validation: Resistance increase <5% through 3-stage acceleration (ambient→60°C→-20°C cycling)

- Lifespan Conversion:”With 20 daily operations, these slides last 13.7 years – surpassing standard 5-year rails.”

3. Corrosion Defense Technology: Coastal-Industrial Salt Spray Resistance

- Dual-Layer Protection:

- Base material: Hot-dip galvanized (80μm) + Nano-ceramic coating

- Salt spray resistance extended from 48hr to 120hr zero-rust (ASTM B117 Class A)

- Acid resistance: pH3.0 acetic acid spray (simulating cleaners) maintains 97% coating integrity

4. Structural Innovation: Military-Grade Material Validation

| Test Parameter | Goodich Performance | Industry Standard |

|---|---|---|

| Bend Strength | 1,820N/mm² | 1,200N/mm² |

| Impact Toughness (-30°C) | 55J | 28J |

| Thickness Tolerance | ±0.05mm | ±0.15mm |

*1.2mm cold-rolled SPCC steel with laser cutting & CNC bending increases rigidity by 40%*

5. SilentGlide™ Technology: Acoustic Lab Certification

- Noise Spectrum Analysis:

https://sample-link- Standard slides: Peak frequency 125-250Hz (human-sensitive range)

- Goodich slides: Peak shifted to >4,000Hz (beyond human perception)

- Core Noise-Reduction Tech:

- Parabolic ball track optimization reduces collision energy

- Polyamide retainers absorb high-frequency vibrations

6. Customization Validation: Extreme Environment Adaptation

Chemical Resistance: Passes 12 industrial solvent immersion tests (methanol, hydraulic oil, etc.)

Cryogenic Lab: -40°C / 5,000 cycles – aviation-grade grease prevents solidification

Tropical Test: 70°C & 95% RH operation – metal fatigue strength decline <3% (vs. >10% industry avg.)

Product Description

| Application | Kitchen, Bathroom, Home Office, Living Room, Bedroom, Dining, Babies and kids, Outdoor, Hotel, Villia, Apartment, Office Building, Hospital, School, Mall |

| Place of Origin | China |

| Usage | Kitchen Drawer,Cabinet Drawer,Office drawer |

| Material | Cold Rolled Stell,Stainless Steel SUS304 |

| Length | 10″-40″(250mm -600mm) |

| Feature | Full extension, Silent, easy installation, Heavy Duty,Soft Close |

| Load Capacity | 31-50kg |

| Certificate | TUV,CE,RoHS,SGS,etc |

| Price | The price can be adjusted according to the quantity |

| Life cycle test | 50, 000 times |

| Payment Terms | T/T, L/C, D/P, West Union, Moneygram |

| Price Terms | EXW,FOB,CFR,CIF |

Application quotation process

Communicate and submit requirements: select model

Review and delivery: Confirm within 1 working day, send after confirming the sample (shipping costs need to be borne by the customer)

Confirm the formal order after receiving the sample: pay the advance payment within 7 working days to enjoy sample fee reduction

Goodich heavy duty drawer runners FAQ

Free Sample Request

Salt spray test report interpretation

Mounting bracket optimization suggestions

Competitive product parameter comparison table

- WhatsApp: +86 15618525178

- Email: info@goodich-hardware.com