Industry Caster

Guangdong Goodich Hardware Co.,ltd

The weight capacities of Industry caster wheels range from 16kg to 5000kg (35 LBS to 11,000 LBS) , and their sizes range from 1″ to 12″.Plastic, nylon, PVC, polyurethane, cast iron, aluminum alloy, rubber, TPR, co-polymer, steel, phenolic, stainless steel, and so on are some of the materials used to make wheels. Both single-wheel and twin-wheel casters are available.

Tips: “Goodich” is a factory direct sales, so we do not accept small orders, the minimum order quantity (MOQ) is 5,000 pieces

Guangdong goodich hardware Co.Ltd

Your best choice

- 5-year warranty

- Highly competitive price, leading the industry

- Ultra-high load capacity

- Impact and wear resistance

- Factory direct sales

- Modular customization service

- Maintenance-free, time-saving and efficiency-enhancing

- 1,000+ models to choose

China Industry Caster Supplier

industry caster manufacturer

Guangdong Goodich Hardware Co. Ltd. has more than 20 years of production experience and rich product line accumulation. It has been sold to more than 100 countries around the world and has established a firm foothold. It can provide customized services to meet the needs of different customers and send out within 7 days.

Industrial caster performance test

We do not talk about “durability”, but only use actual test data to reduce the failure rate to zero; we do not talk about “cost-effectiveness”, but use life and safety to reconstruct the cost formula – choosing the right industry caster is essentially choosing a partner who dares to use extreme tests to promise results.

Hardness test

Test the caster’s resistance to indentation, wear and deformation.

Test standard: Shore hardness (Shore A or D)

Typical values:

Polyurethane caster: 80-95 Shore A

Nylon caster: 60-70 Shore D

Rubber caster: 60-80 Shore A

Significance: The higher the hardness, the stronger the resistance to indentation and deformation, but the flexibility (such as shock absorption needs) must be balanced.

Wear test

Evaluate the durability of industry casters against friction loss.

Test method: DIN 53516 standard (rotational wear test)

Typical values:

High-performance polyurethane: wear ≤50 mm³ (test conditions: 1km rolling distance, 10kg load)

Ordinary rubber: wear 100-200 mm³

Industry requirements: The logistics industry usually requires wear ≤80 mm³.

Load Capacity Test

Verify the maximum load-bearing limit of the caster.

Test categories:

Static load: Maximum load-bearing capacity of the caster when stationary (e.g. 500kg/piece)

Dynamic load: Safe load-bearing capacity during movement (e.g. 200kg/piece)

Safety factor: Industry casters must meet a 3:1 safety factor (e.g. nominal 200kg dynamic load, actual test must reach 600kg without deformation).

Long distance walking test

Test the durability of casters in continuous movement.

Test standard:

Distance requirement: simulate 50-100 km continuous rolling (surface is rough concrete)

Performance index: rolling resistance increase ≤15%, wheel surface wear thickness ≤2mm

Application example: hospital cart casters need to pass 80 km test, wheel diameter error ≤5%

Salt spray test

Evaluate corrosion resistance.

Test standard: ASTM B117 (neutral salt spray test)

Typical values:

Stainless steel casters: no visible corrosion for 500 hours

Galvanized steel casters: no red rust for 72 hours

Plastic casters: not applicable (but chemical corrosion resistance test required)

Pass standard: surface rust area ≤5% (industrial grade requirement).

Electrical resistance test

Prevent static electricity accumulation.

Test standard: IEC 61340 (anti-static standard)

Resistance range:

Antistatic casters: 10^4-10^6 Ω (avoid static electricity accumulation)

Insulated casters: ≥10^12 Ω (for high voltage environment)

Application scenario: Electronic workshop requires surface resistance ≤10^9 Ω.

Brake fatigue test

Inspect the reliability of repeated use of the brake system.

Test method:

Number of cycles: ≥5000 starts and stops (simulating 5 years of use frequency)

Performance requirements: Brake force attenuation ≤10%, displacement after locking ≤2mm

Industry case: Forklift caster brakes must pass 10,000 tests.

Life Assessment Test

Simulates overall durability under long-term use.

Test Standards:

Dynamic Life: Simulates 100,000 rolling cycles (load is 80% of the nominal dynamic value)

Destructive Life: Continuous loading until failure (such as load gradually increases to 300% of the nominal value)

Life Indicators:

Industrial Heavy Duty Casters: ≥5 years (continuous use)

Light Duty Casters: ≥2 years (continuous use)

Product Description

| MATERIAL | pp,pu,PVC,TPR,TPU,Nylon etc |

| color | Transparent, Black, White, Orange, etc |

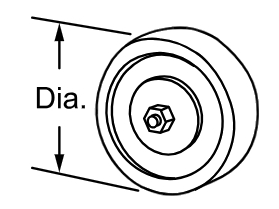

| CUP DIA | 35mm/40mm/45mm/50mm etc,Or customized |

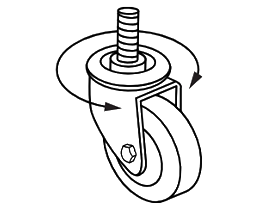

| TYPE | Insert Adaptor, Screw Adaptor, Flat Adaptor etc |

| SAMPLE | free available sample |

| Package | inner bag or bulk package |

| Price Terms | EXW,FOB,CFR,CIF |

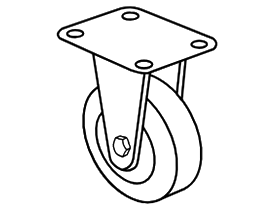

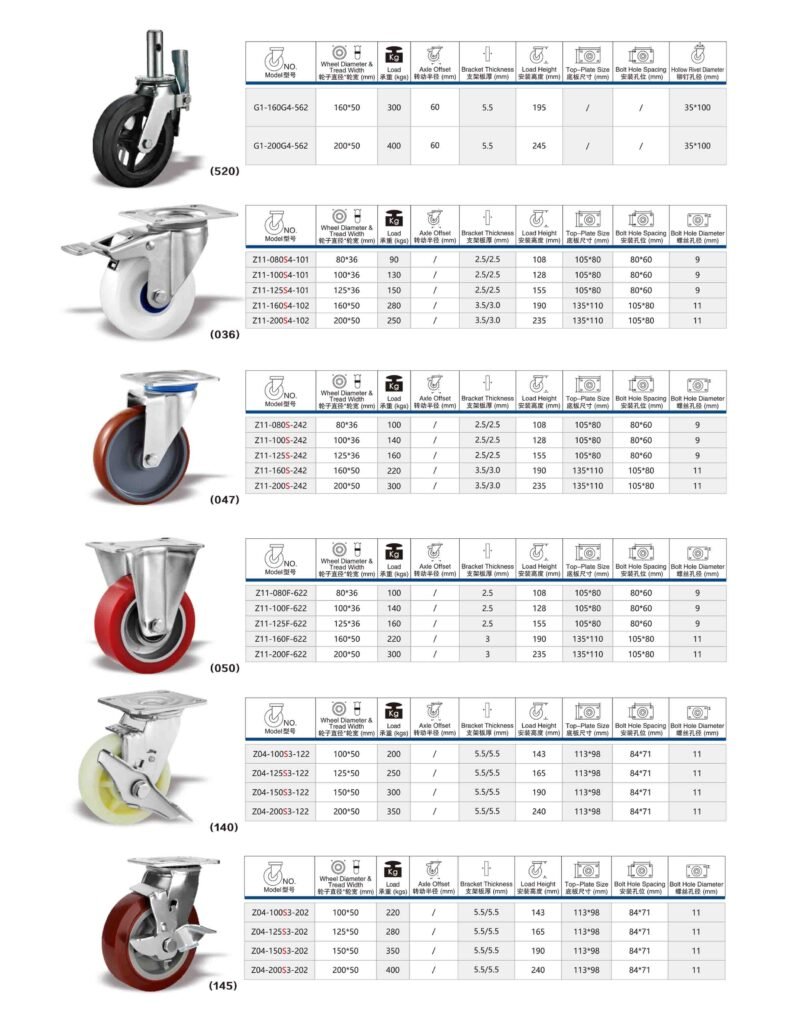

Industry Caster Model

Industry Caster Samples

Before mass production commitment, we open the “Lightning Sample Channel” for you. Submit the request and ship it within 24 hours. During your product performance verification, our sales team will provide 7×12h online communication to promptly answer any questions you encounter during the testing process to ensure the accuracy of the batch order.

Win-win cooperation

Based on your purchase scale, settlement cycle and project characteristics, we provide personalized and customized collaboration solutions: adopt flexible pricing mechanism to match order volume, provide tiered rebate policy and special benefits for annual strategic cooperation; implement dynamic production scheduling mechanism to ensure project production nodes, and achieve monthly precise supply through modular delivery system to ensure that supply chain efficiency and product standards continue to meet your needs.

High-end customization

GOODICH provides highly personalized industry caster and wheel system design services to customers in multiple fields, supporting all-round customization, including load-bearing structure, bracket installation mode, wheel diameter specifications, material selection, etc., helping customers achieve technological iteration and brand enhancement.

OEM/ODM Support

Guangdong Goodich Hardware Co.Ltd

Guangdong Gudi Hardware Co., Ltd. was established in 2002 and is located in Guangdong, China’s manufacturing center. It is a leading precision hardware manufacturer in the global furniture industry. The company focuses on functional components such as drawer slides, hinges, casters and technical accessories, and has 15 automated assembly lines to ensure high-volume precision manufacturing. With two decades of professional experience, Gudi Hardware combines innovative technical capabilities with a strong production system to provide customized solutions for international furniture brands and industrial manufacturers. The company’s focus on R&D-driven adaptability and consistent quality has consolidated global partnerships, making it a driving force for hardware innovation and supply chain reliability.

Industry Caster FAQ

Other Caster

Medical caster

Thousands of items, such as laundry carts and portable resuscitation equipment, must be relocated to […]

Industry caster

The weight capacities of Industry caster wheels range from 16kg to 5000kg (35 LBS to […]

Heavy duty caster

Manufacturer of Heavy Duty Caster Wheels Guangdong Goodich Hardware Co., Ltd. is a supplier of […]

Furniture caster

Furniture caster make it easy to move almost anything, including chairs, couches, tables, cabinets, and […]

Get Quote

After receiving the information, our customer service will contact you in real time via email (info@goodich-hardware.com) or WhatsApp.

We will reply as soon as we see your letter, and we will reply to you in time within 12 hours at the latest.

Guangdong goodich hardware co.ltd

Catalogue

Through the Goodich 2025 version catalog, you can efficiently obtain the detailed parameters of the required model